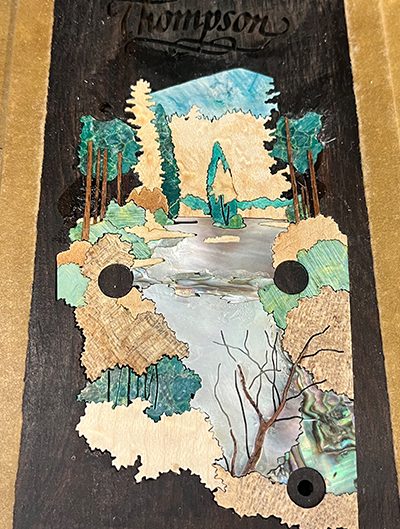

Custom Inlay

INLAY SPECIALIST

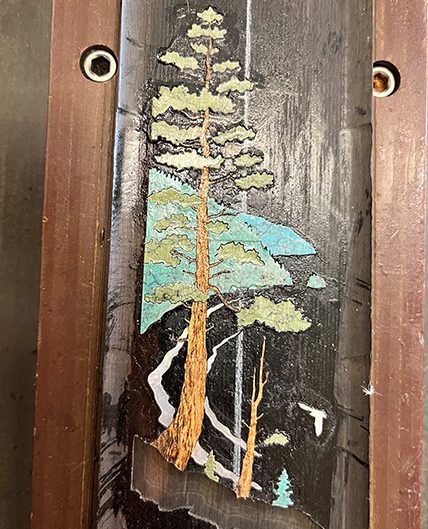

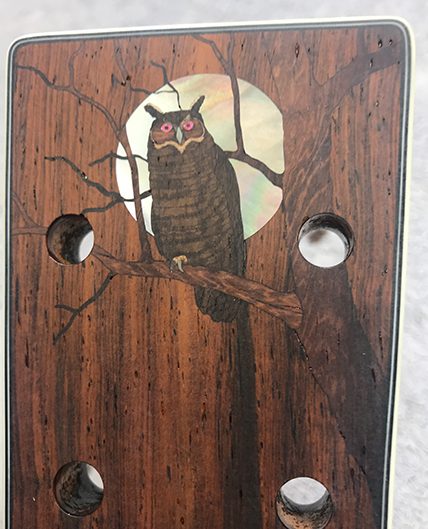

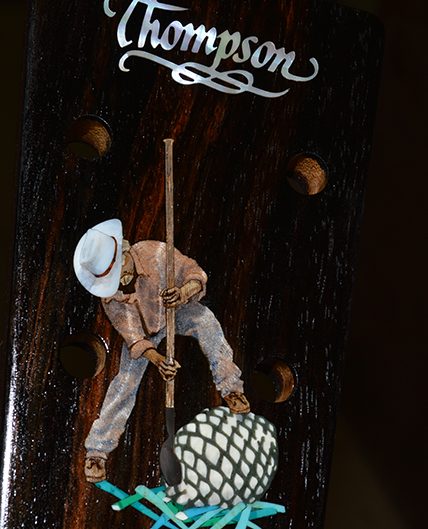

Our inlay specialist, Simon Haycraft, is at the top of his craft with any design creation he immerses himself into. He is the artist behind our spectacular inlays, working closely with Kaleb Klein who runs the CNC machine. Drawing was always a part of Simon’s childhood and studying art at Stratford-upon-Avon College solidified that being an artist was where he thrived and found the most enjoyment.

He went on to study photography, graphics, and illustration at Leamington Spa College of Art and Technology to hone his skills in fine art, allowing Simon to create with precision and depth of scale. His strong interest in nature and wildlife illustrations provide a keen eye towards achieving realistic paintings and detailed wood carvings. His wood carvings can be seen in person at the Orvis Sandanona Shooting Grounds or online at the Sportsman Palette gallery.

INLAY PROCESS

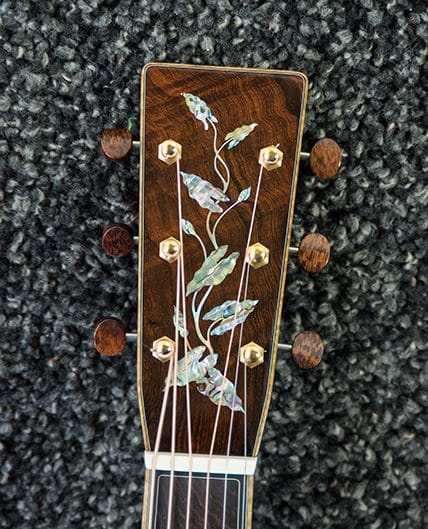

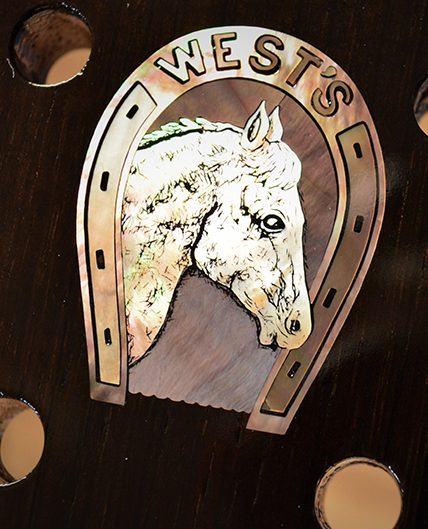

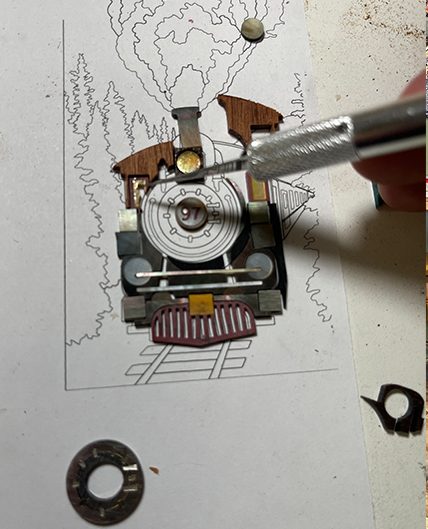

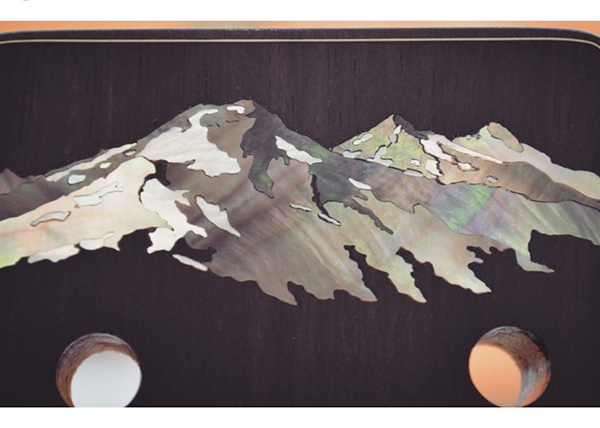

The inlay process starts with a drawing that captures the movement and spirit of the request. The drawings start out with a basic form and moves to more detail as the idea progresses in Simon’s mind and eye. Once the drawing is completed it is incorporated into a computer program and adjusted by Simon to allow for different pieces of inlay to be cut. You can import photos of the actual pieces of abalone, with all their color variations, and then copy and paste a portion of the inlay onto the abalone so that the CNC will cut out the coloring Simon is after for the overall inlay’s look and feel.

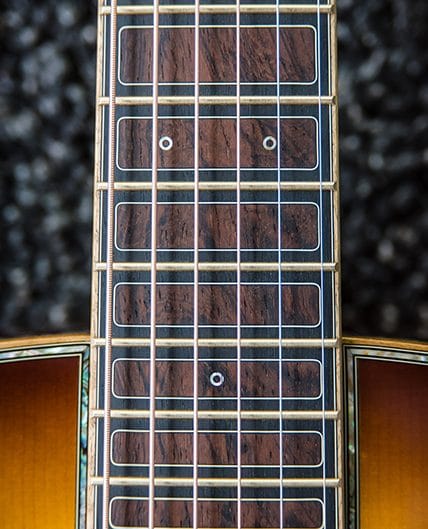

Once the pieces are cut, they can be as small as .050 inches, they are cleaned and laid out on paper towels. The headstock veneer or fretboard have pockets cut out to fit the final inlay in its entirety, but each small piece needs to fit together, be sanded and adjusted to fit like a snug puzzle into the pocket. This job is very tedious and can take a magnifying glass to adjust each one into place. They are glued, sanded flush into the material and then sent onto the finish process.

Lacquer is applied several times and sanded highlighting the luster and natural colors of each piece pearl and shell, bringing it all to life.

Let us know how we can transform one of your favorite images into a custom inlay for your Thompson guitar. We don’t take other already built guitars in special inlay projects, Only if you have just the fretboard or headstock veneer.